Pneumatic Cold Cutting Equipment Rentals & Onsite Service - Split Frame Cold Cutters - Hydraulic Cold Cutting Services & Equipment Rentals - Oilfield Services & Equipment

In addition to eliminating the need for hazardous flame cutting, the cold cutting method enables operators to meet all potential safety requirements, both onshore and offshore.

Hot-Hed®’s air-driven cold cutters are portable, lightweight and compact, allowing for easy transport and quick setup of equipment on any work site. Our split-frame, pneumatic cold cutting equipment produces a lathe-type, beveled or straight cut on pipes or casings up to 32" in diameter.

More Info

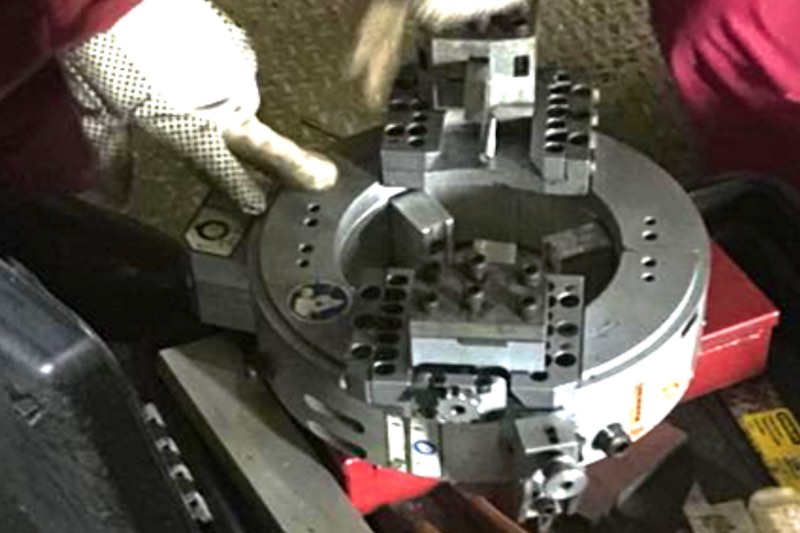

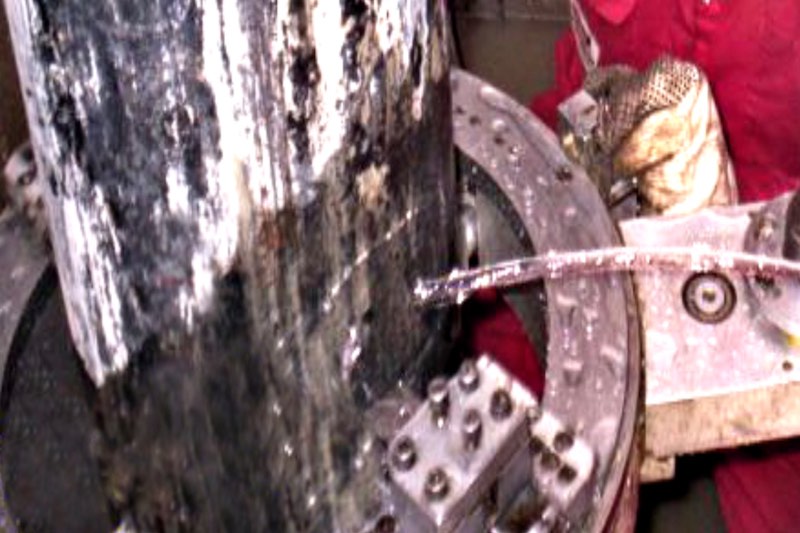

Hot-Hed®’s split frame cold cutters are air driven and capable of both cutting and bevelling all grades of pipe and casing from 7" to 32" O.D. and a wall thickness up to 2-1/2".

Our cold cutting system produces a lathe-type beveled finish on casing ends without altering metallurgical properties. Cutting equipment quickly splits to mount to casing O.D. and requires minimal radial and axial clearance. The cold cutter can be set up and operational in less than 30 minutes.

COLD CUTTING SERVICE FREQUENTLY ASKED QUESTIONS

- How many years has Hot-Hed® been providing Cold Cutting Services to the Oil and Gas Industry and other Industrial Sectors?

Hot-Hed® has been providing Cold Cutting Services to some of the biggest names in Industrial Sectors for 32 years. Our technicians and crews possess the Technical Expertise, Hands-On Experience, Formal Training, In-Depth Knowledge and Work Ethic in all aspects of Cold Cutting, all of which are critical in recognizing details or potential problems that might affect the outcome of any Cold Cutting project. This enables Hot-Hed® crews to consistently deliver Safe Solutions for all of our clients. You can rest assured that your project will be completed Safely & Professionally, every time. - What makes Hot-Hed®'s Cold Cutting Services, Technicians and Crews a Superior Choice over your company’s competitors Cold Cutting Services?

In addition to standard Pipe Cutting Services, Hot-Hed® has a Proven Track Record of Providing Custom Solutions to our clients, as well as providing Specialty Services which are unique to Hot-Hed. Hot-Hed® has Extensive Experience in Cold Cutting Exotic Materials such as Inconel, as well as Counterboring. We have executed Large Pipe Cutting Projects where Multiple Hot-Hed® Cold Cutting crews were required to complete a Time Sensitive Project comprised of Cutting 1000 x 28 inch Heavy Wall Inconel Cladded Pipes.

As part of a Critical Offshore Jacket Installation, we provided Expert Advice in regards to a Safe and Time-Sensitive Cold Cutting Solution for a number of 60” Diameter Heavy Wall Pipes (3” thick), including Mitre Cuts, in order to meet the client's requirements.

Hot-Hed® also Provides Solutions to Prevent potential Environmental Pollution resulting from our Pipe Cutting activities, ensuring your company’s HSE Requirements are Met and / or Exceeded.

In addition to offering Pipe and Casing Cutting Services, we have developed Module Attachments to Execute Custom Pipe Cutting Solutions, such as External Pipe Turning in order to reduce overall OD of pipe.

Hot-Hed®’s Highly Skilled Machinists are Experts in operating various types of Cold Cutting Machines and Ancillaries, and are Especially Proficient in Adapting to a wide range of challenging work environments. Many Pipe Cutting and Casing Cutting projects go beyond conventional Cold Cutting activities. Challenges associated with on- site Machining are unique to each work environment, requiring Unique Solutions. Because of their Experience, Training and Expertise, as well as their Ability to Recognize Crucial Details on the job, Hot-Hed® Cold Cutting Technicians are well- known for delivering our clients Consistently Safe and Secure Solutions. - How does Hot-Hed®'s Cold Cutting Equipment Enhance Operational Efficiency?

Hot-Hed®'s Air-Driven Cold Cutters are lightweight, portable and easy to set up, making them perfect for all fast-paced Industrial Operations. Our Cold Cutting Equipment can be transported effortlessly to various job sites and be fully operational in under 30 minutes, Minimizing Downtime and keeping your project on track, ultimately Increasing Revenue and Production. - Why choose Hot-Hed®'s Cold Cutting Services? What are the Benefits to Our Company? What about Our Company’s HSE Requirements?

In addition to Increasing Revenue and Production, Hot-Hed®'s Cold Cutting Services offer a much Safer Alternative to flame cutting, eliminating hazards such as sparks and heat. Cold Cutting is ideal for Safety-Sensitive Environments, both onshore and offshore, ensuring your company is able to Meet all Safety / HSE Requirements, without compromising on precision. - Our company’s project involves some very Challenging Work Environments, including areas with Minimal Clearance. Can Hot-Hed®’s Cold Cutting Equipment get the job done in these kinds of Tight Spaces?

Hot-Hed®'s Split Frame Cold Cutters require Minimal Radial and Axial Clearance, making them Ideal for Operations In Confined Spaces Or Areas With Restricted Access. The Flexibility of our Cold Cutting Equipment, along with the Expertise of our Highly Trained Technicians and Crews, ensures We Can Complete Your Company’s Project Safely and Efficiently, even in challenging environments. - Can Hot-Hed®’s Cold Cutting Equipment handle Different Pipe Materials and Sizes? Will the Metallurgical Properties of the pipe be compromised?

Our Split-Frame Cold Cutters can handle a Wide Range of Pipe Grades, from 1” to 60” in outside diameter (O.D.) and have managed Wall Thicknesses of up to 3”. This makes Hot- Hed®'s Cold Cutting Equipment ideal for Diverse Industrial Operations. The Cold Cutting method Preserves the Integrity of Pipe Metallurgical Properties. It delivers a Clean, Lathe-Type, Beveled Finish without introducing any heat, ensuring the pipe’s Metallurgical Properties Remain Unchanged. - Which Industries can Benefit from Hot-Hed®’s Cold Cutting Services, and how?

Due to the Safety Benefits of Cold Cutting Services – such as the absence of heat, sparks or flames, which Minimize the Risk of Accidents in hazardous environments – a Wide Range of Industries can Benefit from Hot-Hed®’s Cold Cutting Services.

• Oil and Gas Industry

• Petrochemical Industry

• Construction Industry

• Shipbuilding and Maritime Industries

• Aerospace and Defense Industries

• Manufacturing Industries

• Materials Processing Industries

• Pharmaceutical Industry